Nikel Alloy 75 / Nimonic 75

Lembar Data Teknis

| Watesan Komposisi Kimia | ||||||||

| Bobot% | Ni | Cr | Ti | C | Si | Cu | Fe | Mbak |

| Paduan 75 Nimonic 75 | Bal | 18.9 - 21.0 | 0.2 / 0.6 | 0.08 / 0.15 | 1,0 maks | 0,5 maks | 5,0 maks | 1,0 maks |

Alloy 75 (UNS N06075, Nimonic 75) yaiku campuran 80/20 nikel-kromium kanthi tambahan titanium lan karbon sing dikontrol. Nimonic 75 nduweni sifat mekanik sing apik lan resistensi oksidasi ing suhu dhuwur. Paduan 75 paling umum digunakake kanggo nggawe logam lembaran sing mbutuhake oksidasi lan resistensi skala, uga kekuatan medium ing suhu operasi sing dhuwur. Alloy 75 (Nimonic 75) uga digunakake ing mesin turbin gas, kanggo komponen tungku industri, kanggo peralatan lan perlengkapan perawatan panas, lan teknik rekayasa nuklir.

Properti Mekanikal Khas

| Materi | Tes Temp ° F | Kekuwatan Tensile Ultimate (ksi) | 0,2% Kekuwatan ngasilake (ksi) | Elongation ing 2 " |

| Paduan 75 Lembar 1925 ° F Anneal | Kamar | 114.4 | 59.4 | 31 |

| Paduan 75 Lembar 1925 ° F Anneal | 1000 | 105.6 | 51.9 | 27 |

| Paduan 75 Lembar 1925 ° F Anneal | 1200 | 69.3 | 40.0 | 32 |

| Paduan 75 Lembar 1925 ° F Anneal | 1400 | 41.4 | 22.0 | 75 |

| Paduan 75 Lembar 1925 ° F Anneal | 1600 | 20.2 | 9.9 | 90 |

| Paduan 75 Lembar 1925 ° F Anneal | 1800 | 9.7 | 4.4 | 91 |

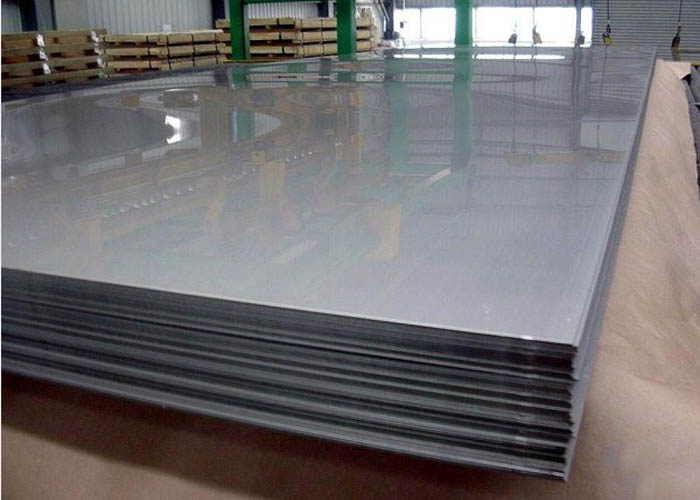

Kasedhiyan

Alloy 75 (Nimonic 75) kasedhiya ing Bar, Bar Round, Bar Flat, Plate, Strip, Sheet, Wire, Tube, Rod, Stock Forging lan Extruded.

Kandel: 0,05-3,0mm

Diameter: 0,08--500mm

OD: 10-500mm, WT: 2.0-100mm

Nilai liyane sing bisa diwenehake:

Paduan 31

Paduan 33

Paduan 36

Paduan 42

Paduan 46

Paduan 52

Paduan 32-5

Paduan 2917

Paduan 59

Hastelloy B

Hastelloy B-2

Hastelloy B-3

Hastelloy B-4

Hastelloy C

Hastelloy C-4

Hastelloy C-22

Hastelloy G-50

Hastelloy G

Hastelloy G-3

Hastelloy G-30

Hastelloy G-2000