Alat Baja Dingin Baja Flat bar 1.2379 / D2

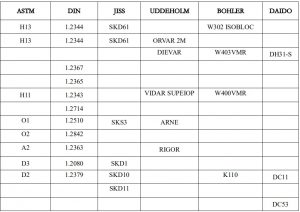

| Standar | DIN | AISI | JIS | ГТ |

| X155CrVMo12-1 | 1.2379 | D2 | SKD11 | 12МФ |

Bahan kimia composisi (analisis khas ing%)

C | Si | Mbak | P | S | Cr | Mo | V |

1.45-1.60 | 0.10-0.40 | 0.15-0.45 | 0.030 | 0.030 | 11.0-13.0 | 0.70-1.00 | 0.70-1.10 |

_____________________________________________________________________________________________________________

Sifat baja: | Baja Chrome-molibdenum-vanadium kanthi ketahanan sing kuat kanggo pengerasan minyak lan udhara, utamane resistensi sing dhuwur (luwih saka 1.2080), daya pemotong sing apik, tekanan sing kuwat, kenceng ngisor (nanging luwih dhuwur tinimbang 1.2080) . Baja iki nuduhake stabilitas dimensi sing apik ing perawatan panas, cocog kanggo pengerasan nganti sekunder sekunder (kemungkinan nitriding). Luwih saka waja iki angel banget diasah, bisa digunakake kanthi panas kanthi angel lan bisa kerja kanthi angel ing negara sing dicakup. |

______________________________________________________________________________________________________________

Aplikasi: | Motong, nubuk, alat stamping, agul-agul gunting, mati gulung utas, alat gambar lan mlengkung, gulungan flensa lan pelurus, alat gambar jero, cetakan plastik kanggo polimer kasar, mati ekstrusi kadhemen, tilem tilem |

______________________________________________________________________________________________________________

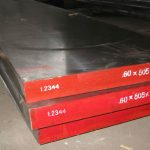

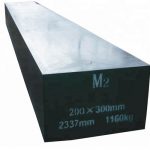

| Ukuran sawetara: | Diameter (mm) | Kandel (mm) | Jembar (mm) |

8 - 450 | 8 - 350 | Maksimum 810 |

______________________________________________________________________________________________________________

Kondisi pangiriman: | Lembut anil nganti maksimal 250 HB |

______________________________________________________________________________________________________________

Perawatan Panas:

| Annealing alus | Suhu (° C) | Adhem | Atose |

800 - 850 | tungku | maks. 250 HB |

| Forging | Suhu (° C) | Adhem | |

850 - 1050 | tungku |

| Atos | Suhu (° C) | Adhem | Tempering |

1000 - 1090 | lenga utawa udhara utawa adus panas | ndeleng diagram tempering biasane 150 - 540 ° C |

Komentar: Kabeh informasi teknologi mung kanggo referensi.

Nilai liyane sing bisa diwenehake.