S32750 S32205 2205 2507 904L S31803 Lembar Stainless Steel Duplex

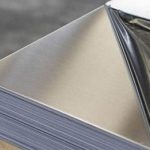

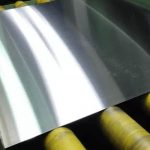

2205 2507 904L S32750 S32205 S31803 Produk sheet stainless steel duplex digunakake kanggo bagean stamping logam, bagean peralatan mekanik gedhe, lan sasis. Lan aksesoris elektronik cilik, macem-macem suku cadang perangkat keras. piring stainless steel duwe resistensi asam, tahan alkali, kekuatan tarik lan kekuatan panen. Luwih cocog kanggo polesan, ora ana blister ing lumahing, pinhole lan liya-liyane. Uga duwe resistensi anti-sensitisasi sing kuat kanggo suhu dhuwur.

| Sasmita | 2205 2507 310S 904L S32750 S32205 S31803 Lembar stainless steel duplex |

| Proses | Panas digulung utawa Cold kadhemen |

| Perawatan lumahing | No.1 / 2B / No.4 / HL / Disikat / BA / 8K Mirror / Embossed / Etched etc. (Kanthi kertas Kertu utawa PVC kanggo nglindhungi) |

| Standar | JIS, AISI, ASTM, GB, DIN, EN, lsp. |

| Kandel | Digulung adhem (0.3-3mm). Panas digulung (3-100mm) |

| Jembar | 600-2000mm utawa kaya sing disesuaikan |

| Dawane | 1000-6000mm utawa kaya sing disesuaikan |

| Merek | TISCO, BAO STEEL, BAOXIN, ZPSS, LISCO, JISCO, lsp. |

| Paket | Paket Laut Ekspor Standar (Kertas Kraft Waterproof + Pallet Kayu + Bundle kanthi strip baja) |

| Ukuran Standar | 4 'x 8' ---------- 1220mm x 2348mm 4 'x 10' --------- 1220mm x 3048mm 5 'x 10' --------- 1524mm x 3048mm 5 'x 20' --------- 1524mm x 6096mm |

Spesifikasi piring stainless steel TISCO

| Rentang toleransi kekandelan lembaran / piring stainless steel sing digulung | ||||

| Kandel | Toleransi Gedhe | Toleransi Normal | Toleransi Cilik | Ora Toleransi |

| 0,4MM | 0.3-0.32 | 0.33-0.37 | 0.37-0.39 | ≥0.39 |

| 0,5MM | 0.4-0.42 | 0.43-0.47 | 0.47-0.49 | ≥0,49 |

| 0,6MM | 0.5-0.52 | 0.53-0.56 | 0.57-0.59 | ≥0.59 |

| 0,7MM | 0.6-0.62 | 0.63-0.67 | 0.67-0.69 | ≥0.69 |

| 0,8MM | 0.7-0.72 | 0.73-0.77 | 0.74-0.79 | ≥0,79 |

| 0.9MM | 0.8-0.82 | 0.83-0.87 | 0.87-0.89 | ≥0,89 |

| 1.0MM | 0.89-0.9 | 0.91-0.94 | 0.94-0.99 | ≥0,99 |

| 1.2MM | 1.02-1.08 | 1.09-1.15 | 1.16-1.18 | 1.18 |

| 1,5MM | 1.32-1.38 | 1.39-1.45 | 1.46-1.48 | ≥1.48 |

| 2.0MM | 1.72-1.79 | 1.8-1.86 | 1.87-1.9 | ≥1.9 |

| 2,5MM | 2.23-2.36 | 2.32-2.42 | 2.42-2.47 | ≥2,48 |

| 3.0MM | 2.7-2.77 | 2.78-2.85 | 2.85-2.9 | ≥2.9 |

Rentang toleransi kekandelan lembaran / piring stainless steel sing digulung panas | ||||

Kandel | Toleransi Gedhe | Toleransi Normal | Toleransi Cilik | Ora Toleransi |

3.0MM | 2.6-2.75 | 2.75-2.85 | 2.86-2.9 | ≥2.9 |

4.0MM | 3.5-3.6 | 3.6-3.75 | 3.76-3.95 | ≥3.95 |

5.0MM | 4.5-4.6 | 4.6-4.75 | 4.75-4.95 | ≥4,95 |

6.0MM | 5.4-5.6 | 5.6-5.75 | 5.75-5.85 | ≥5,85 |

8.0MM | 7.3-7.5 | 7.5-7.65 | 7.65-7.85 | ≥7.85 |

10.0MM | 9.2-9.3 | 9.3-9.6 | 9.6-9.85 | ≥9.85 |

12.0MM | 11.1-11.2 | 11.2-11.6 | 11.6-11.85 | ≥11.85 |

14.0MM | 13.1-13.2 | 13.2-13.6 | 13.6-13.85 | ≥13.85 |

Komposisi Kimia lan sifat mekanik:

| ASTM | C% | Mn% | P% | S% | Si% | Cr% | Ni% | Mo% |

201 | ≤0.15 | 5.5-7.5 | 0.06 | ≤0.03 | ≤1.00 | 16.0-18.0 | 3.5-5.5 | - |

202 | ≤0.15 | 7.5-10.0 | 0.06 | ≤0.03 | ≤1.00 | 17.0-19.0 | 4.0-6.0 | - |

301 | ≤0.15 | ≤2.00 | 0.045 | ≤0.03 | ≤1.00 | 16.0-18.0 | 6.0-8.0 | - |

304 | 0.08 | ≤2.00 | 0.045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 8.0-10.5 | - |

304L | ≤0.03 | ≤2.00 | 0.045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 8.0-12.0 | - |

309S | 0.08 | ≤2.00 | 0.045 | ≤0.03 | ≤0.75 | 22.0-24.0 | 12.0-15.0 | - |

310S | 0.08 | ≤2.00 | 0.045 | ≤0.03 | ≤1.50 | 24.0-26.0 | 19.0-22.0 | - |

316 | 0.08 | ≤2.00 | 0.045 | ≤0.03 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

316L | ≤0.03 | ≤2.00 | 0.045 | ≤0.03 | ≤0.75 | 16.0-18.0 | 10.0-14.0 | 2.0-3.0 |

317L | ≤0.03 | ≤2.00 | 0.045 | ≤0.03 | ≤0.75 | 18.0-20.0 | 11.0-15.0 | 3.0-4.0 |

321 | 0.08 | ≤2.00 | 0.045 | ≤0.03 | ≤0.75 | 17.0-19.0 | 9.0-12.0 | - |

347 | 0.08 | ≤2.00 | 0.045 | ≤0.03 | ≤0.75 | 17.0-19.0 | 9.0-13.0 | - |

405 | 0.08 | ≤1.00 | 0.04 | ≤0.03 | ≤1.00 | 11.5-14.5 | ≤0,60 | - |

409 | 0.08 | ≤1.00 | 0.045 | ≤0.03 | ≤1.00 | 10.5-11.75 | ≤0,50 | - |

430 | ≤0.12 | ≤1.00 | 0.040 | ≤0.03 | ≤0.75 | 16.0-18.0 | ≤0,60 | - |

434 | ≤0.12 | ≤1.00 | 0.040 | ≤0.03 | ≤1.00 | 16.0-18.0 | - | - |

444 | 0.025 | ≤1.00 | 0.045 | ≤0.03 | ≤1.00 | 17.5-19.5 | ≤1.00 | - |

403 | ≤0.15 | 5.5-7.5 | 0.04 | ≤0.03 | ≤0,50 | 11.5-13.0 | ≤0,60 | - |

410 | ≤0.15 | ≤1.00 | 0.035 | ≤0.03 | ≤1.00 | 11.5-13.5 | ≤0,60 | ≤1.00 |

420 | 0.16~0.25 | ≤1.00 | 0.04 | ≤0.03 | ≤1.00 | 12.0-14.0 | ≤0.75 | ≤1.00 |

440A | 0.60~0.75 | ≤1.00 | 0.04 | ≤0.03 | ≤1.00 | 16.0-18.0 | - | ≤0.75 |

SAD2507 | ≤0.03 | ≤1.2 | 0.035 | 0.02 | ≤0,80 | 24.0-26.0 | 6.0-8.0 | 3.0-5.0 |

SAF2205 | ≤0.03 | ≤2.0 | ≤0.03 | 0.02 | ≤1.00 | 21.0-23.0 | 4.0-6.5 | 2.5-3.5 |

904L | ≤0.0.3 | ≤2.0 | 0.035 | ≤0.03 | ≤1.00 | 18.0-20.0 | 23.0-25.0 | 3.0- |

nglereni sheet stainless steel, slitting, mriksa, mriksa kaping pindho, lapisan PVC, pengepakan, pengiriman.